Secrets from Below Deck

How we engineer our retractable systems to last and last and last…

What might cause a retractable seating system to break down?

- Is it how often it is used? Rarely.

- Is it HOW it is used? Sometimes, if it is not operated correctly.

- Is it how it is engineered? Often, yes. Some retractable seating systems, although they may work perfectly well at first, have some inbuilt demons that will surface over time. Here are the top three pitfalls we avoid to make sure ours last 25, 30 years or more.

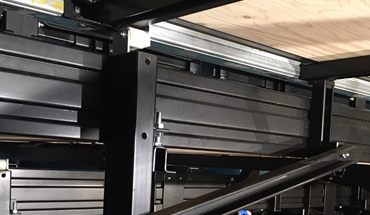

1. Metal-to-metal contact

Imagine a knee joint where the cartilage has worn away. The first sign may be stiffness, the second pain – in the end the knee may become difficult to move at all. It’s the same with retractable systems. Metal-to-metal contact in the joints of retractable system causes wear, and eventually the system may seize. Audience Systems ensure that all points of contact where load is transferred from one part of the system to the other have “cartilage” – ie nylon pads or rollers – helping operators to avoid the “pain” (sorry) of breakdowns.

2. Guidance Issues

If one side of a retractable system tries to open faster than the other, components may catch or jar against each other. At best, this will cause wear, at worst, the platforms will seize. Audience Systems use a highly robust hinged steel alignment system to ensure that left and right open out in one smooth, perfectly co-ordinated glide. This ensures not only top marks from the judges, but also a long and happy life for the seating system.

The adjustability of our platforms ensure they work in harmony with settling of the building over time; nylon rollers and pads at contact points prevent the considerable wear (and noise!) that metal-to-metal contact can cause.

3. Adjustment Issues

Newly constructed buildings usually experience some kind of settling of the floor. A retractable seating system relies on load being transferred down a number of columns to the ground. If the floor settles, more weight may come to rest on some columns more than others. While this may not be an immediate problem, over time it can cause wear and ultimately failure. Audience Systems have specifically designed our system to counter this by utilising an adjustment mechanism that allows the system to be re-balanced every year by our service engineers. Some systems which rely more heavily on welding are more difficult to adjust - and are therefore more prone to wear or failure.

There are many other things we do that enhance the reliability of our systems: the robust materials and fixings we use, the care we take to individually engineer each system, the fact that we manufacture all platforms at our UK headquarters, the diligent checks we perform during installation and the comprehensive aftersales and support package we offer. But these three features underneath our deck, which the people operating the system will barely notice (and why should they?!) are keeping thousands of our systems running smoothly, every day.